PET PLASTIC BOTTLE APPLICATION SCOPE THE USE OF PET PLSTIC BOTTLES IN DAILY LIFE Beverage package PET plastic bottles are common beverage packaging materials, such…

Category: Company news

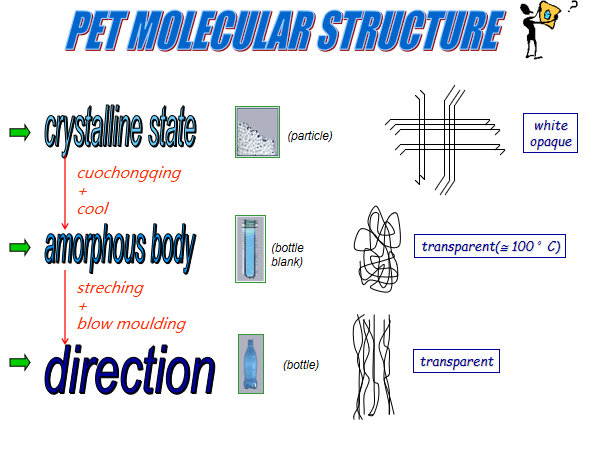

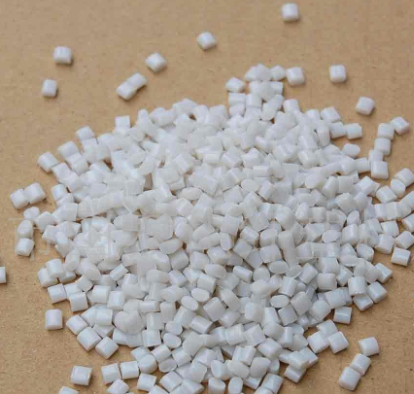

1.The material of the bottle PET is used as a material. Then what is PET is and what is it features? How do particles became…

Are pet plastic bottles poisonous? Pet plastic bottles are non-poisonous at room temperature. Pure PET begins to degrade at 250-300°C, but volatile toxic products are…

As a plastic raw material, PET mainly includes polyethylene terephthalate PET and polybutylene terephthalate PBT. Polyethylene terephthalate is also commonly known as polyester resin. It…

PET bottle blowing machine principle and technical process At present, most of the PET bottle blowing machine are still two-step blow molding machines, that is,…

What is the advantage of PET plastic bottle blowing machine? In daily life, using a PET plastic bottle blowing machine can effectively remove part of…

PC 5 gallon barrel is produced by special PC extrusion machine. The high-quality PC 5 gallon barrel is hard and high finished. It can not…

PET preform mold design steps list Step 1: Analyze 2D and 3D deawings 1. The geometric shape of the product 2. The size, tolerance and…

PET plastic bottle can be divided into two categories, one is a pressure bottle, such as a bottle filled with carbonated beverages; the other is…

PET Bottle Blowing Machine Features The heater tunnel and blowing platform are separated, which shortens the mold opening time, improves the blowing speed, and increases…

Wini

Wini